- Tips for Designing the Perfect Backyard Retreat

- ThoughtSol Infotech is Certified as the 'Great Place To Work' in the Fifth Consecutive Year

- Samsung India Launches the 2nd Season of 'Samsung Innovation Campus' National Skilling Programme to Empower Youth

- HCLTech appoints Lee Fang Chew as Independent Director

- Princeton Psychotherapy Center Introduces Innovative Therapies for Breakups and Chronic Pain

- MindCypress Hosts Successful IFRS Webinar for Finance Professionals

- Kirill Kupchenko, Director of After-sales Services at AVTODOM MKAD, spoke about the service of electric vehicles Zeekr

- Advertising Maverick Tridib Ghosh Launches Game-Changing Advanced Generative AI Course

- CLIRNET Teams Up with African Medical Associations to Revolutionize Healthcare Education

- Grossman Chevrolet to provide Old Saybrook Little League with new equipment, monetary contribution

- Motion Education aces the JEE exam, recording a selection ratio of 68.01%

- Mars Wrigley launches BOOMER Jelly on Top Boomer, Goes Wobbly with Bumrah for Maximum Fun

- The Shoreline Unveils Premier Co-op Apartments in New Rochelle, Redefining Luxury Living

- Vedanta FACOR and CFlo Partner for Sustainable Chrome Beneficiation in Odisha

- Authorized Economic Operator (AEO) Status Now Extended To The Gem & Jewellery Sector

Mail to a Friend Mail to a Friend |

|

|

HIOTron Presents a Conclusive guide on Condition Monitoring in Industry 4.0

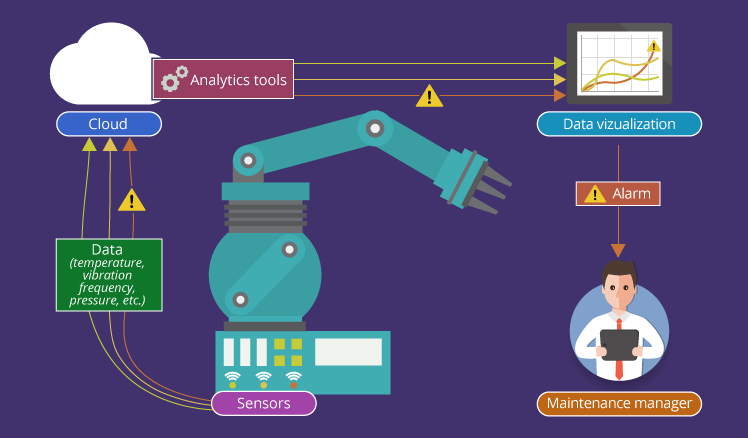

Pune, Maharashtra, India., October 10, 2019 - hIOTron presents a guide on Condition Monitoring on the Way to Industry 4.0 which simply monitoring the condition of an asset. Before the emergence of Industry 4.0, usually scheduled preventive maintenance was the primary method used to reduce downtime.

As per the ITIC survey, 98% of establishments report losing at least $100,000 per hour of downtime, out of those 33% surveyed claiming to lose from $1 million to $5 million per hour.

IoT predictive maintenance schemes fall under condition monitoring (CM), which is the process of remarking machinery condition parameters in order to recognize changes that are representative of a developing fault.

Condition Monitoring Applications in various Industries:

Discrete manufacturing

CM technologies such as ultrasound material thickness testing, motor current signature analysis (MCSA), lubricant analysis and infrared thermography can transfer data to a management platform that can monitor the data and identify damage that will lead to the loss.

Automotive Fleets

Condition Monitoring IoT systems also can construct a profile of each fleet driver to analyze their effect on the vehicle?s condition, which is helpful for controlling driver risk and determining any operator weakness

Process Manufacturing

In the pulp and paper industry, condition monitoring is utilized to trace the condition and the arrangement of rolls and roll balance.

Upstream Oil and Gas

The capacity to analyze offshore drillings in real-time from a single location is the reason behind upstream oil and gas companies move to Industrial IoT development.

Electric Power

Condition monitoring enables power plants to assure reliable power generation.

Construction

IoT-based condition monitoring is broadly referred to follow the health and operating parameters of heavy machinery.

Advantages of IoT Condition Monitoring:

The core benefits can be summarized as follows:

1. Minimize maintenance costs

2. Maximized Production

3. Optimized inventory of spare parts

4. Increased machinery lifetime

5. Precise and relevant data for driving product development

Condition Monitoring fits into the general Industry 4.0 framework as a basic block for constant improvement. IoT-based condition monitoring supplies a strong foundation for process and ROI optimization.

Links:

To know more about Condition Monitoring on the Way to Industry 4.0: https://www.hiotron.com/condition-monitoring/

About hIoTron:

hIOTron Pvt.Ltd (hIOTron's) provide a practical study for various IoT cloud platforms. hIOTron had deployed over 21000 IoT Devices. hIoTron's IoT Platform helps businesses to connect and manage data securely.

It also Develops, supports and manufactures IoT platforms and serving 55+ Fortune Enterprises.

hIOTron offers an End-To-End IoT Solutions over such platforms with End-To-End Classroom IoT Training (https://www.hiotron.com/iot-training/) in Mumbai and Pune with which you can easily come up with new ideas and techniques.

Company :-hIOTron

User :- rasika Joshi

Email :-rasika@hiotron.com

Phone :-08208896758

Url :- https://www.hiotron.com/iot-training/